Table of Contents

Maintain maximum selectivity and increase the efficiency of your operation with the ACL Pallet Shuttle. A Radio Shuttle, also known as a pallet runner, is a semi-automatic storage and retrieval system that maximizes warehouse space. The shuttle car can move along the track inside the storage aisle and is easily managed by remote control.

Warehouse operations run more smoothly because forklifts do not have to access racks, reducing the risk of accidents.

The forklift only leaves the load on the track, and the pallet shuttle automatically picks it up and moves it. The trays are as compact as possible, each slotted in its place. Since forklifts do not need to drive into the driveway, loading and unloading times are shorter, and storage capacity is higher and deeper.

In other words, the Pallet Shuttle System provides a compact storage solution that reduces operating costs and improves supply chain performance, enabling optimal smart warehousing.

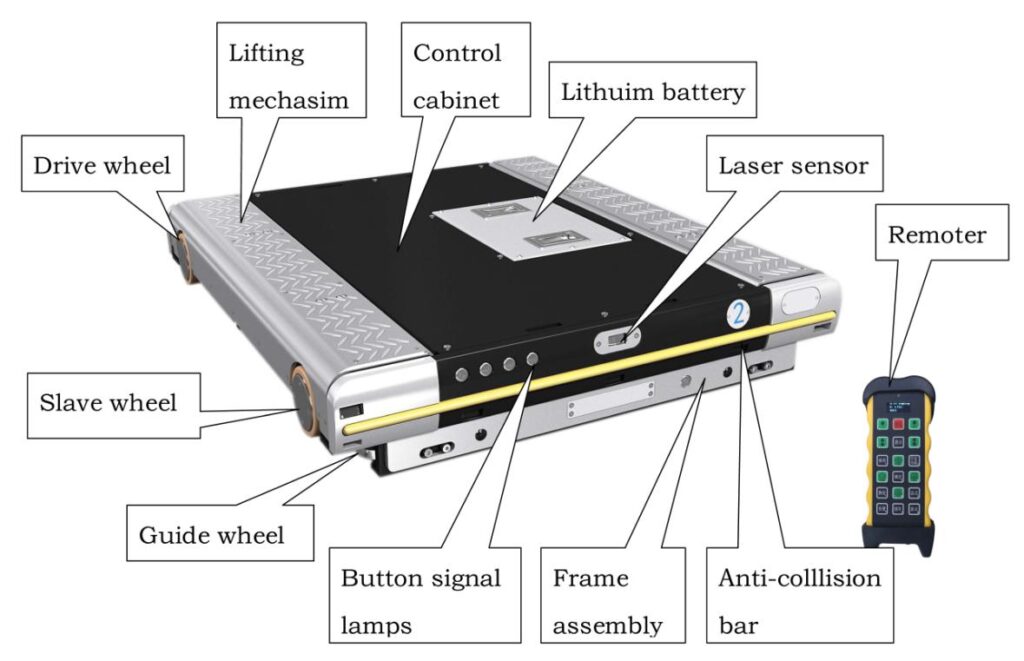

ACL Radio Shuttle consists of a base platform equipped with wheels to enable it to move, a pallet lifting system on the shuttle itself, and a long list of sensors and detection readers that collect information from its environment and enforce safety measures.

The shuttle is equipped with different status indicators to inform the operator of any possible error, battery level, or whether it is on or off.

Our Radio Shuttle comes in 8 styles: Economic Type, Standard Type, High-configuration type, Heavy loading type, and Low temp. type, Wifi type, Stacker type, M/S type. The following two tables are their technical parameters.

| Parameters | Economic type | Standard type | Advanced type | Heavy load type |

|---|---|---|---|---|

| Loading capacity max. | Max 1500kg | Max 1500kg | Max 1500kg | Max 2000kg |

| Running speed | Vmax_empty: 1.0m/s Vmax_full: 0.8m/s | Vmax_empty: 1.2m/s Vmax_full: 0.8m/s | Vmax_empty: 1.5m/s Vmax_full: 1.0m/s | Vmax_empty: 0.8m/s Vmax_full: 0.6m/s |

| Drive motor | Domestic brush /brushless servo motor 48VDC 600W | Imported brush servo motor 48VDC 600W | Imported brushless servo motor 48VDC 600W | Domestic brush motor 48VDC 800W |

| Servo driver | Domestic customized servo driver | Domestic customized servo driver | Imported brushless servo driver | Domestic customized servo driver |

| Lift motor | Domestic motor 48VDC 450W | Imported motor 48VDC 500W | Imported motor 48VDC 500W | Domestic motor 48VDC 540W |

| Lift height | ≤45mm | ≤45mm | ≤45mm | ≤45mm |

| Move positioning: Laser sensor | Germany P+F/SICK | Germany P+F/SICK | Germany P+F/SICK | Germany P+F/SICK |

| Pallet positioning: Laser sensor | Germany P+F/SICK | Germany P+F/SICK | Germany P+F/SICK | Germany P+F/SICK |

| Lift control: | proximity switch | Germany P+F | Germany P+F | Germany P+F/SICK |

| Object detection: photosensor | Germany P+F/SICK | Germany P+F/SICK | Germany P+F/SICK | Germany P+F/SICK |

| Control system | Siemens S7-200 PLC | Siemens S7-200 PLC | Siemens S7-200 PLC | Siemens S7-200 PLC |

| Remoter: two-way | Customized IMT | Customized IMT | Customized IMT | Customized IMT |

| Power supply | Lithium battery | Lithium battery | Lithium battery | Lithium battery |

| Battery capacity | 48V, 30AH | 48V, 30AH | 48V, 30AH | 48V, 40AH |

| Running time | ≥8h | ≥8h | ≥8h | ≥8h |

| Charging time | 3~4H | 3~4H | 3~4H | 3~4H |

| Battery lifetime | Charge times≤1000 | Charge times≤1000 | Charge times≤1000 | Charge times≤1000 |

| Operation mode | Remote control | Remote control | Remote control | Remote control |

| Running noise | ≤60db | ≤60db | ≤60db | ≤60db |

| Painting color | Frame (black) Others (light gray) | Frame (black) Others (light gray) | Frame (red) Others (light gray) | Frame (black) Others (light gray) |

| Ambient temperature | Temp: 0℃~50℃ Humidity: 5%~95% | Temp: 0℃~50℃ Humidity: 5%~95% | Temp: 0℃~50℃ Humidity: 5%~95% | Temp: 0℃~50℃ Humidity: 5%~95% |

| Parameters | Low-temperature type | Wifi type | Stacker type | M/S type |

|---|---|---|---|---|

| Maximum payload | Max 1500kg | Max 1500kg | Max 1500kg | Max 1500kg |

| Running speed | Vmax_empty: 1.0m/s Vmax_full: 0.8m/s | Vmax_empty: 1.5m/s Vmax_full: 1.0m/s | Vmax_empty: 1.5m/s Vmax_full: 1.0m/s | Vmax_empty: 1.5m/s Vmax_full: 1.0m/s |

| Drive motor | Imported brush servo motor 48VDC 600W | Imported brushless servo motor 48VDC 600W | Imported brushless servo motor 48VDC 600W | Imported brushless servo motor 48VDC 600W |

| Servo driver | Domestic customized servo driver | Imported brushless servo driver | Imported brushless servo driver | Imported brushless servo driver |

| Lift motor | Imported motor 48VDC 500W | Imported motor 48VDC 500W | Imported motor 48VDC 500W | Imported motor 48VDC 500W |

| Lift height | ≤45mm | ≤45mm | ≤45mm | ≤45mm |

| Move positioning: Laser sensor | Germany P+F/SICK | Germany P+F/SICK | Germany P+F/SICK | Germany P+F/SICK |

| Pallet positioning: Laser sensor | Germany P+F/SICK | Germany P+F/SICK | Germany P+F/SICK | Germany P+F/SICK |

| Lift control: proximity switch | Germany P+F | Germany P+F | Germany P+F | Germany P+F |

| Object detection: photosensor | Germany P+F/SICK | Germany P+F/SICK | Germany P+F/SICK | Germany P+F/SICK |

| Control system | Siemens S7-1200 PLC | Siemens S7-1200 PLC | Siemens S7-1200 PLC | Siemens S7-1200 PLC |

| remoter: two way | Customized IMT | Customized IMT | Spare domestic | Spare domestic |

| Power supply | Lithium battery | Lithium battery | Lithium battery | Lithium battery |

| Battery parameter | 48V, 40AH | 48V, 30AH | 48V, 30AH | 48V, 30AH |

| Run time | ≥8h | ≥8h | ≥8H | ≥8H |

| Charging time | 3~4H | 3~4H | 3~4H | 3~4H |

| Battery lifetime | Charge times≤1000 | Charge times≤1000 | Charge times≤1000 | Charge times≤1000 |

| Operation mode | Remote control | WCS dispatch/ Remote control | WCS dispatch/ Remote control | WCS dispatch/ Remote control |

| Running noise | ≤60db | ≤60db | ≤60db | ≤60db |

| Painting | Frame (black) Others (light gray) | Frame (red) Others (light gray) | Frame (red) Others (light gray) | Frame (black) Others (light gray) |

| Ambient temperature | Temp: -25℃~50℃ Humidity: 5%~95% | Temp: 0℃~50℃ Humidity: 5%~95% | Temp: -25℃~50℃ Humidity: 5%~95% | Temp: 0℃~50℃ Humidity: 5%~95% |

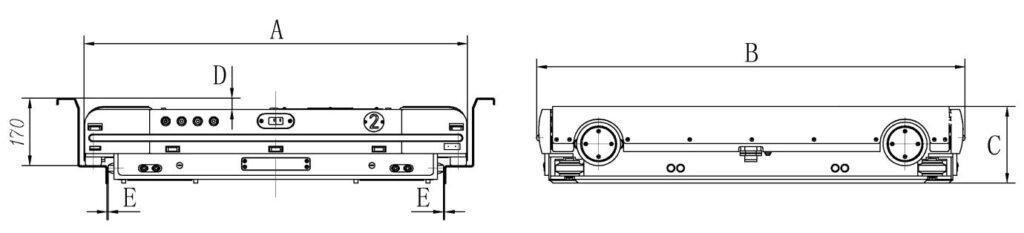

| Model | Pallet sizes (mm) | Weight (kg) | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) |

|---|---|---|---|---|---|---|---|

| ACLII-1012 | 1000X1200 | 285 | 831 | 1270 | 193 | 27 | 3 |

| ACLII-1113 | 1100X1300 | 295 | 873 | 1370 | 193 | 27 | 3 |

| ACLII-1210 | 1200X1000 | 280 | 957 | 1070 | 193 | 27 | 3 |

| ACLII-1211 | 1200X1100 | 290 | 957 | 1170 | 193 | 27 | 3 |

| ACLII-1212 | 1200X1200 | 300 | 957 | 1270 | 193 | 27 | 3 |

| ACLII-1213 | 1200X1300 | 310 | 957 | 1370 | 193 | 27 | 3 |

| ACLII-1214 | 1200X1400 | 320 | 957 | 1470 | 193 | 27 | 3 |

| ACLII-1215 | 1200X1500 | 335 | 957 | 1570 | 193 | 27 | 3 |

| ACLII-1216 | 1200X1600 | 345 | 957 | 1670 | 193 | 27 | 3 |

| ACLII-1311 | 1300X1100 | 300 | 1057 | 1170 | 193 | 27 | 3 |

| ACLII-1410 | 1400X1000 | 310 | 1157 | 1070 | 193 | 27 | 3 |

| ACLII-1411 | 1400X1100 | 320 | 1157 | 1170 | 193 | 27 | 3 |

| ACLII-1412 | 1400X1200 | 330 | 1157 | 1270 | 193 | 27 | 3 |

| ACLII-1414 | 1400X1400 | 355 | 1157 | 1470 | 193 | 27 | 3 |

| ACLII-1415 | 1400X1500 | 365 | 1157 | 1570 | 193 | 27 | 3 |

Note:

Different dimensions of radio shuttle can be tailor-made as per various kinds of pallets and rails.

Pallet sizes, i.e. 1200X1000 (front number 1200 means fork-in direction /width direction, rear number 1000 means width direction)

The rescue vehicle of the radio shuttle is equipment to drag the radio shuttle to the cargo rack port, when the radio shuttle cannot move on the rack due to trouble. Manual mode is adopted to make forward or backward with the handle.

The operating method is as follows:

First of all, the rescue vehicle is forked to the radio shuttle rail by forklift, then the operator moves the rescue vehicle to the faulty radio shuttle. Firstly switch off the main power supply of the radio shuttle, then connect the radio shuttle to the rescue vehicle by the hook. Then move them to the cargo rack port by the manual handle. Remove the hook, then fork out the rescue vehicle and radio shuttle separately.

The charging cabinet, equipment to charge the battery of the radio shuttle, has two charging positions. The charging position circuit is designed with an independent power supply, which can charge two batteries simultaneously or charge one battery together. Charging will automatically stop when the battery is fully charged. The charging cabinet has simple operation and convenient application.

When working on higher racks, forklift operators often drop off radio shuttles due to insufficient sight or less experience. In order to solve this problem, our company has developed a set of auxiliary placement systems for the radio shuttle, which can provide the forklift with a visual interface to prevent the radio shuttle from dropping off by misoperation.

When a radio shuttle is rescued by a rescue vehicle, the radio shuttle with cargo is hardly dragged out if the radio shuttle is on heavy duty. By means of this auxiliary system, pallets can be firstly placed on the rail, then radio shuttle directly dragged out!